packed bed reactor design

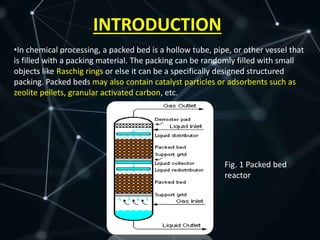

In design the number of necessary theoretical equilibriumstages is first determined and then the packing height equivalentto a Theoretical plat packing height required is the number theoretical stages multipliedby the HETP. MBBR moving bed biofilm reactor media biological growth support products.

Exothermic Packed Bed Reactor System Covered With The Countercurrent Download Scientific Diagram

A moving bed biofilm reactor MBBR is a biological process dedicated to moving or circulating a biocarrier which plays a role in the process of nitrification and denitrification in a bioreactor for removing organic matter.

. A fluid bed reactor is sometimes used whereby the catalyst particles which are very fine sit on a distributor plate. The rotating bed reactor is a rather new invention. Gas pressure drop per m of bed.

Random Packed Bed Spherical ball packing - packs extremely well little to no settle. Scrubber design for pharma scrubber calculations scrubber design. Packed bed reactors can be used in chemical reaction.

Here are some links to example problems dealing with packed bed reactors. MBBR is also an activated sludge process but with a more efficient biocarrier performance. Packed with palladium at ca 350.

And which settles with the packed bed. Like a CSTR in that the reactants are well mixed. Limitations of each process design and performance characteristics of different kinds of bioreactors developed starting from stirred.

The resulting medium then has many properties and characteristics of normal fluids such as the ability to free-flow. Various processes that have been successfully developed for wastewater treatment treatment of industrial wasteseffluents have been surveyed with special reference to biological treatment including design of bioreactors. The variance for reactor 1 reactor 2 and reactor 3 is 204383596213811 min2 229201369687755 min2 and 17943456129332 min2 respectively.

The acrylonitrile process for example capitalizes on this benefit. 21 m Considered value. When the basket is spinning immersed in a fluid phase the inertia forces created by the spinning motion forces the fluid outwards thereby creating a circulating flow through the rotating packed bed.

Scrubber design for pharma scrubber calculations scrubber design. The mean residence time for reactor 1 reactor 2 and reactor 3 is 70192579 min 67902629 min and 28008597 min respectively. 62 are the simplest type pf reactor to design and consist of solid catalyst particles being loaded and packed into the bedHowever there are often problems faced with the plastic feed such as high viscosities low thermal conductivities and irregular shape when being placed inside the reactor.

A rotating bed reactor RBR holds a packed bed fixed within a basket with a central hole. The design of the reactor is determined by many factors but of particular importance are the thermodynamics and kinetics of the chemical reactions being carried out. 4th Generation Design Structured Metal Packing 304 and 316 SS Standard Raschig USA Inc.

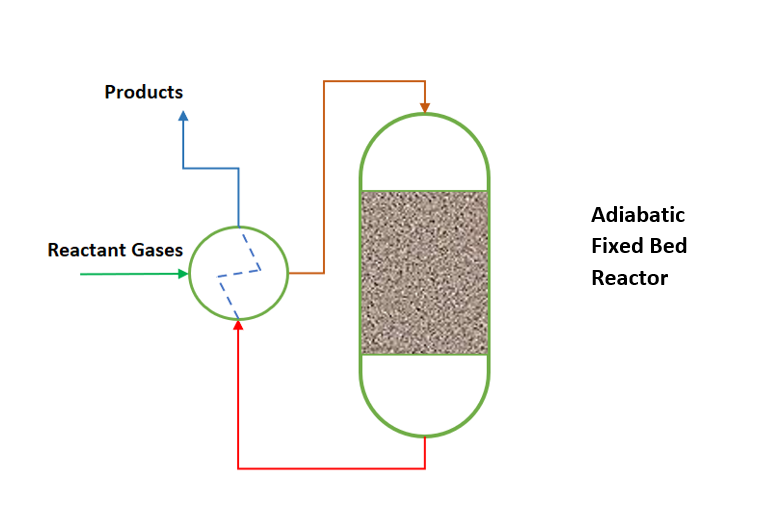

Moving bed biofilm reactor. Fixed bed reactors Fig. Packed bed reactor Siegel MH Robinson CW 1992 Packed beds can either be run in the submerged mode with or without aeration or in the trickle ow mode.

Assumptions that will be useful in the later stage of the reactor design can be made use on the CSTR of the process. A fluidized bed is a physical phenomenon that occurs when a solid particulate substance usually present in a holding vessel is under the right conditions so that it behaves like a fluidThe usual way to achieve a fluidize bed is to pump pressurized fluid into the particles. The restrainer is required since the packing material is ceramic and keeping the integrity of the.

Design a Scrubber Packed column UPDATED as on 07022020. You could also use these problems as self tests. Even for the most extreme exothermic reactions a fluidized bed can maintain an iso-thermal profile within a few degrees.

PBR Type 1 Home Problem. Kinds of Phases Present. Three moments is determined to shows the behaviour of the RTD Function in the CSTR.

15 mmWC m of bed Considered Value Packing factor Fp. Steady state conditions with constant inlet reactants and outlet flow products. Ten times greater than that in a packed-bed reactor.

Moving particles especially small particles can transport heat much more efficiently than gas alone.

Simplified Diagram Of A Laboratory Based Packed Bed Bioreactor 21 Download Scientific Diagram

Pdf Simulation Of A Packed Bed Reactor Semantic Scholar

Packed Bed Reactor Chemical Reactor Transparent Png 640x835 Free Download On Nicepng

Deep Conversion In Packed Bed Reactors German Indian Partnership Program Fau And Iitd

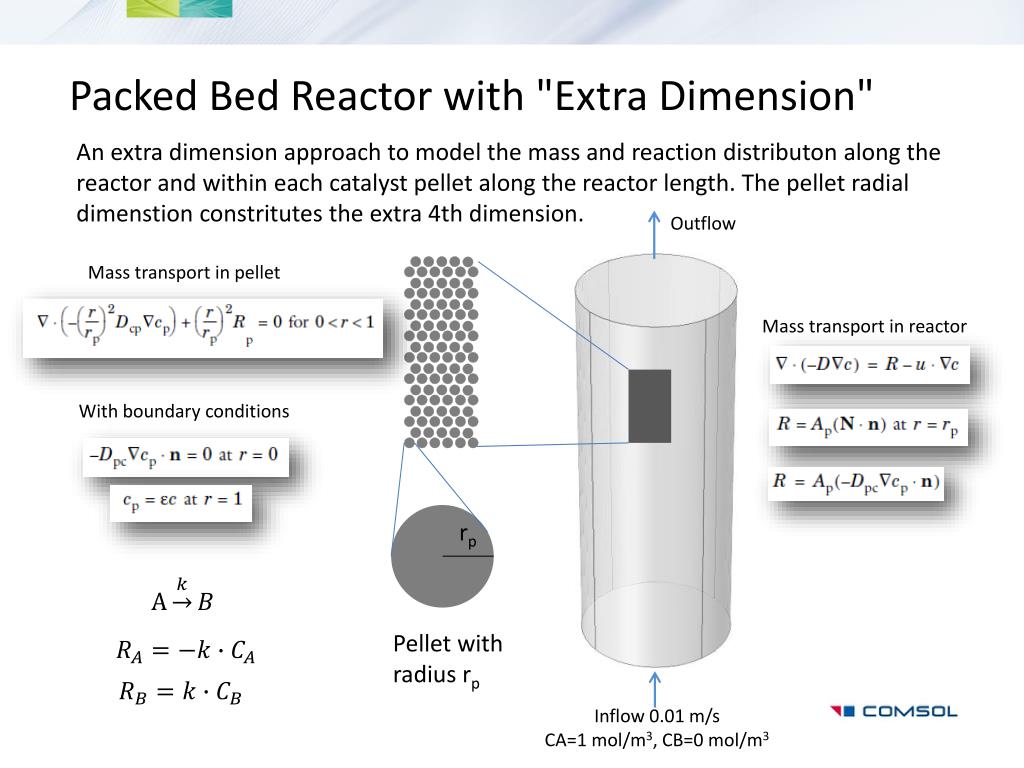

Ppt Packed Bed Reactor With Extra Dimension Powerpoint Presentation Id 2420870

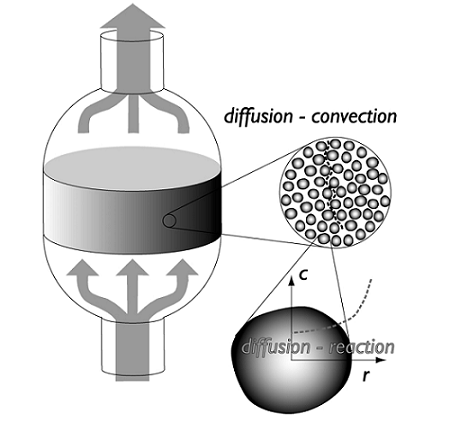

What Is A Packed Bed Reactor Comsol Blog

Chemical Reactor Packed Bed Trickle Bed Reactor Fluidized Bed Reactor Catalysis Png 655x932px Chemical Reactor Bioreactor

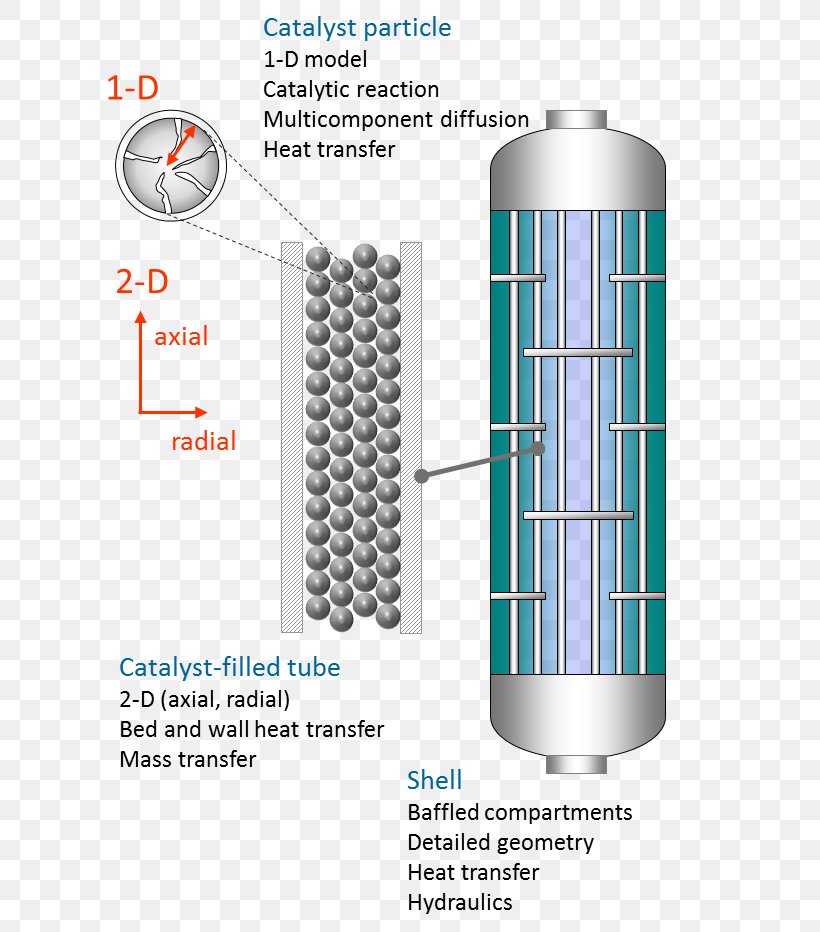

Fixed Bed Reactor An Overview Sciencedirect Topics

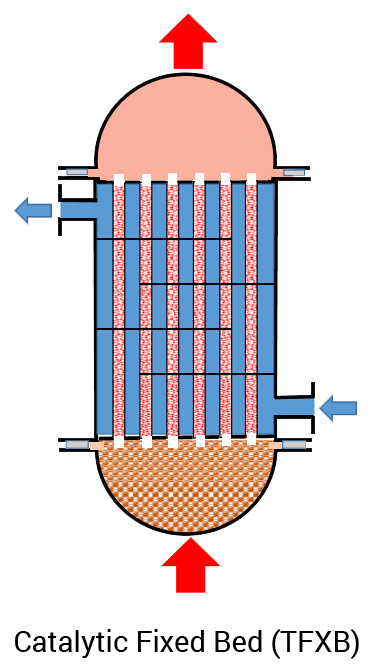

Homogeneous And G S Catalytic Reactors Cstr Spinning Basket Packed Multi Tubular Bayonet Tube Bubbling Circulating Entrained Bed

Fixed Bed Reactor An Overview Sciencedirect Topics

Packed Bed And Fluidised Bed Bioreactor Youtube

Fixed Bed Reactor Chemengghelp

Figure 1 From Modeling Of A Catalytic Packed Bed Reactor And Gas Chromatograph Using Comsol Multiphysics Semantic Scholar

Description Of Reactors Petroleum Refining

Schematic Diagram Of The Packed Bed Reactor Download Scientific Diagram

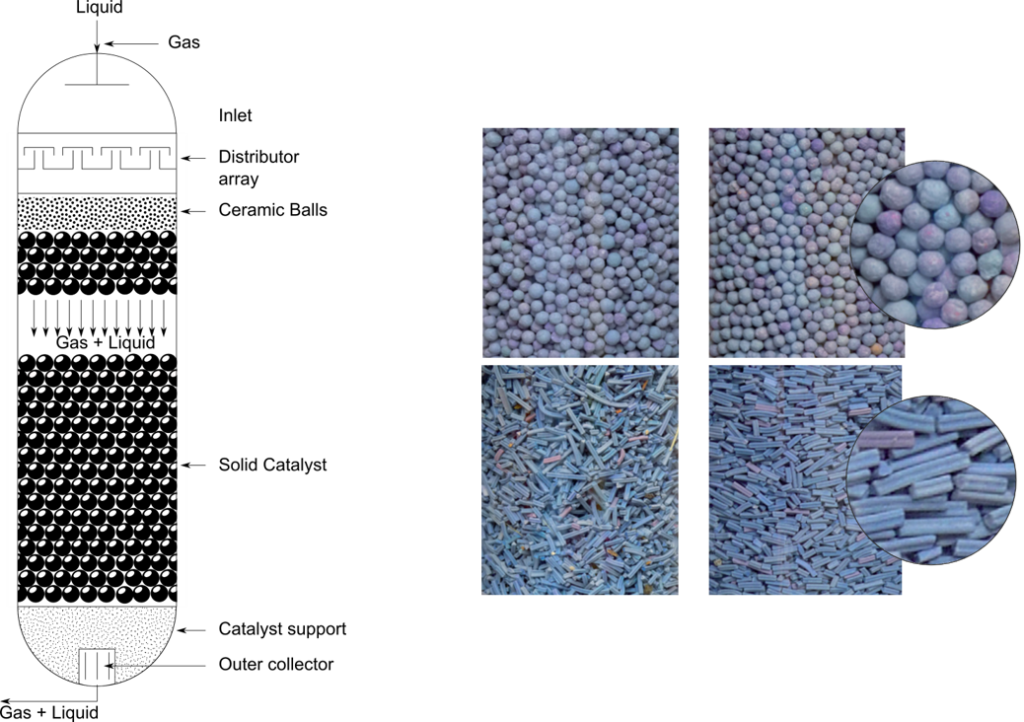

Packed Bed Reactors For Gas Liquid Solid Catalyzed Systems 65 A Download Scientific Diagram

No comments for "packed bed reactor design"

Post a Comment